Temp-Ex is a Regenerative Industrial Manufacturer

Temp-Ex is the 2nd generation of Sedef Inc. It takesits values and capabilities from Sedef . Creativity is fuelled by a holistic perspective. All processes are based on observation and analysis. The work is carried out by a team that blends material knowledge and industrial design with curiosity for research and development. While meeting our human needs, it does this by developing flexible and passive solutions that can / care about the network instead of the supply chain. By passive, we mean solutions that do not require an active energy source such as electricity or diesel during use. It prioritises the raw materials used in its solutions to have an ecological footprint as low as possible, even recyclable and compostable. It does not only talk about its ethical values, but also endeavours with a high awareness to put them into practice.

What does sustainability mean for Temp-Ex?

To the wolf, to the bird, to the food…

What does performance tests mean for Temp-Ex?

Performance testing of thermal covers is a crucial step in ensuring product protection throughout the whole cool chain. This critical step is nowadays carried out experimentally, which is a time and resource-intensive method. During these tests, thermal cover manufacturers are using different experimental setups and data processing methods. This non-standardized approach leads to numerous incomparable products in the market and confused clients with questions like “How many data loggers were used?”, “Where were the data loggers positioned?”, “How were the temperatures statically obtained?”.

Besides the experimental performance tests, Temp-Ex also utilizes also the numerical performance tests using computational fluid dynamics (CFD) simulations. These simulations are carried out within an hour, which makes it less time and resource consuming compared to the experiments. Continuous validation studies exhibit an excellent agreement between experimental and numerical performance tests.

A result of such a CFD simulation is shown above. The high resolved temperature field in the product allows obtaining the minimum, maximum and average temperature statically. Flow simulation around the product leads to a more accurate convection calculation under different scenarios like in the cold store, on the tarmac and in the aircraft. The solar radiation calculation is carried out wavelength-dependent so that the direct, diffuse and ground-reflected radiation can be modelled. Such a detailed radiation calculation is crucial for an accurate assessment of the thermal covers reflectivity performance. Numerical performance tests are also capable of calculating complex tasks like phase change phenomena (e.g., PCMs).

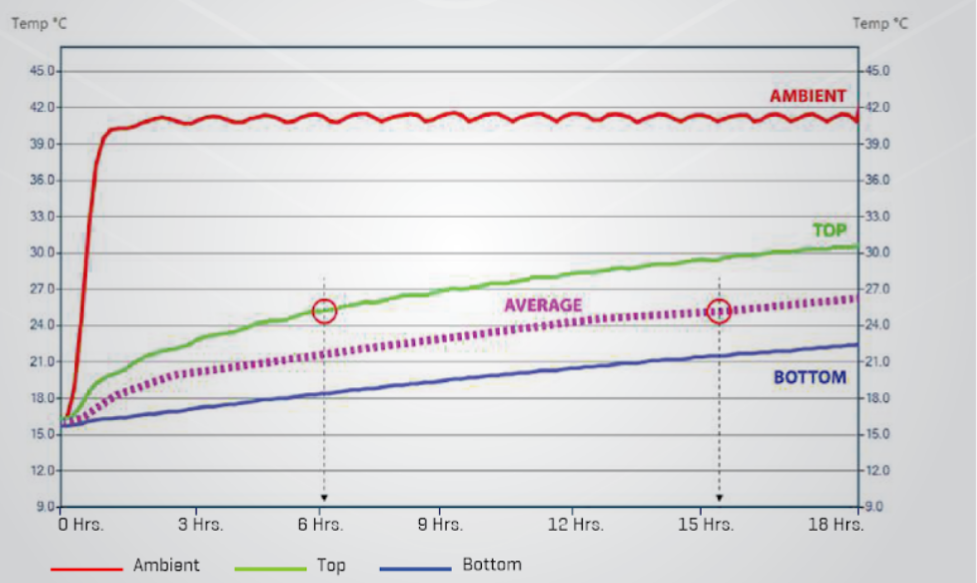

The Average Dilemma

As shown in the figure below, the most critical point of the thermal cover is its top surface. The temperature value on this surface exceeds the 15-25°C critical range circa after six hours. On the other hand, if the average value of the experimental temperature data is considered, the limit value of 25°C is reached after circa 15 hours. In other words, considering average temperature values result in thermal performance which is more than doubled compared to the thermal performance determined using particular temperature values.

In order to avoid such statistical illusions, SIL simulations are utilized to identify the critical points in the system. Following these results, the thermal performance is then validated using these critical points (points with the maximum and/or fastest deviation from the critical range).

Temp-Ex is a Regenerative Industrial Manufacturer

Temp-Ex is the 2nd generation of Sedef Inc. It takesits values and capabilities from Sedef . Creativity is fuelled by a holistic perspective. All processes are based on observation and analysis. The work is carried out by a team that blends material knowledge and industrial design with curiosity for research and development. While meeting our human needs, it does this by developing flexible and passive solutions that can / care about the network instead of the supply chain. By passive, we mean solutions that do not require an active energy source such as electricity or diesel during use. It prioritises the raw materials used in its solutions to have an ecological footprint as low as possible, even recyclable and compostable. It does not only talk about its ethical values, but also endeavours with a high awareness to put them into practice.

What does sustainability mean for Temp-Ex?

To the wolf, to the bird, to the food…

What does performance tests mean for Temp-Ex?

Performance testing of thermal covers is a crucial step in ensuring product protection throughout the whole cool chain. This critical step is nowadays carried out experimentally, which is a time and resource-intensive method. During these tests, thermal cover manufacturers are using different experimental setups and data processing methods. This non-standardized approach leads to numerous incomparable products in the market and confused clients with questions like “How many data loggers were used?”, “Where were the data loggers positioned?”, “How were the temperatures statically obtained?”.

Besides the experimental performance tests, Temp-Ex also utilizes also the numerical performance tests using computational fluid dynamics (CFD) simulations. These simulations are carried out within an hour, which makes it less time and resource consuming compared to the experiments. Continuous validation studies exhibit an excellent agreement between experimental and numerical performance tests.

A result of such a CFD simulation is shown above. The high resolved temperature field in the product allows obtaining the minimum, maximum and average temperature statically. Flow simulation around the product leads to a more accurate convection calculation under different scenarios like in the cold store, on the tarmac and in the aircraft. The solar radiation calculation is carried out wavelength-dependent so that the direct, diffuse and ground-reflected radiation can be modelled. Such a detailed radiation calculation is crucial for an accurate assessment of the thermal covers reflectivity performance. Numerical performance tests are also capable of calculating complex tasks like phase change phenomena (e.g., PCMs).

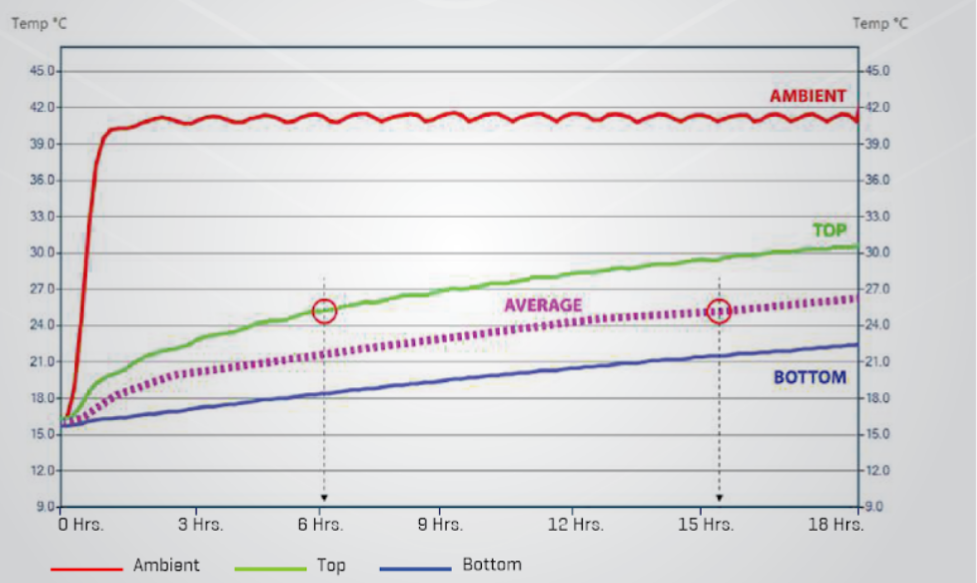

The Average Dilemma

As shown in the figure below, the most critical point of the thermal cover is its top surface. The temperature value on this surface exceeds the 15-25°C critical range circa after six hours. On the other hand, if the average value of the experimental temperature data is considered, the limit value of 25°C is reached after circa 15 hours. In other words, considering average temperature values result in thermal performance which is more than doubled compared to the thermal performance determined using particular temperature values.

In order to avoid such statistical illusions, SIL simulations are utilized to identify the critical points in the system. Following these results, the thermal performance is then validated using these critical points (points with the maximum and/or fastest deviation from the critical range).